MERLIN Operator Portal

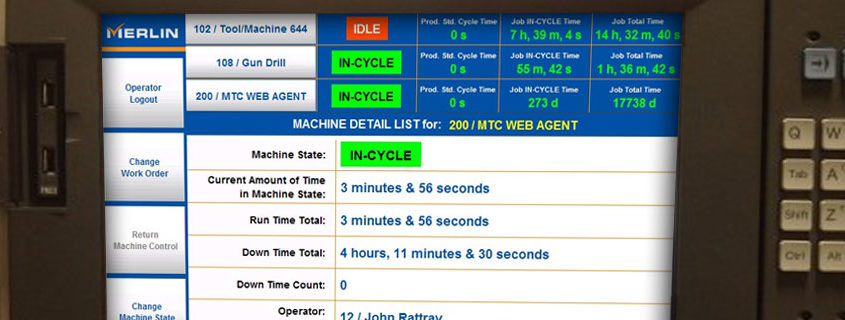

Real-Time Machine Operation/Process Operation Display Human Machine Interface (HMI)

The MERLIN Operator Portal is an intuitive application that displays critical The MEMEX smart manufacturing tool-kit does an exception job of connecting all machines on the factory floor, capturing data, and offering dashboard analytics. It also utilizes one of the most valuable assets on the factory floor – human intelligence – with the MERLIN Operator Portal.

The MERLIN Operator Portal is a Windows based Human Machine Interface (HMI) that provides operators with a live window into what information is being collected from the machine(s), in real-time. Operators can trigger procedural and function processes which affect the data collected on the work order/shop order/job running at their machines.

Touch-screen optimized and barcode ready, the MERLIN Operator Portal virtually eliminates data input errors. Just as MERLIN Tempus dashboards are integral to operational analytics, the MERLIN Operator Portal is integral to the rapid adoption of new, innovative processes on the shop floor. It provides machine operators with an easy-to-use interactive tool that captures information, and informs them as they carry out their tasks. It is an essential tool enabling operators to gather and classify critical downtime states, part rejects and part counts. It enables an operator to interact with work orders in real-time and send alerts to colleagues.

Demands on operator time and expanded responsibility continue to grow. The MERLIN Operator Portal empowers operators who use it to provide critical, databased input about production disruptions and work execution. This captured data also reduces paperwork. This leaves operators with more time to focus on relevant work instructions and production-related information such as mechanical drawings.

Features & Benefits

Features:

- The Operator Portal is designed to run on Windows OS.

- Deployment can be on tablets, computers, laptops and touch screen systems

- The application is untethered from specific machines providing the ability for operators to manage and monitor multiple machine assets at the same time

- Provides the means to visually present critical information to the CNC machine operator

- Allows the operator to log into the database that is collecting critical information from the machine

- It will prompt a user for critical down time information from any asset being monitored

- Operators can view and select production orders for any machine and monitor their operation, part count, and machine utilization all in real-time

- Operators can monitor all assets for which they are collecting data

- Pro-active email alerts can be sent out by the operator for any machine monitored for rapid response, such as maintenance, supervision and quality

Benefits:

- Intuitive design

- Resizable display

- User customizable information screen

- Real-time queue for production orders

- Operator auto-prompt for down-time reasons

- Touch screen support

- Barcode ready for production order interaction

- Built in onscreen barcodes

- Part quality classification and part count

- Optional paperless shop feature

- Fully integrates with MERLIN Tempus and Tempus EE

- Enhances any shop operation

Next Steps

Book an Appointment

Talk to a MEMEX representative

Attend a Webinar

Watch a live MERLIN demo

How to

Buy

Find a dealer or buy direct

Learn

More

Download feature sheet